Solid Wood Edges on an Oval Table

This discussion of wood movement and the practicalities of constructing and oval table includes some nice photos of contributors' work. January 14, 2013

Question

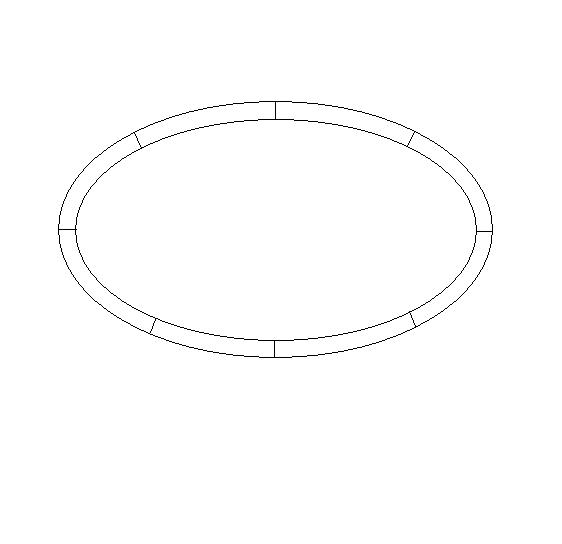

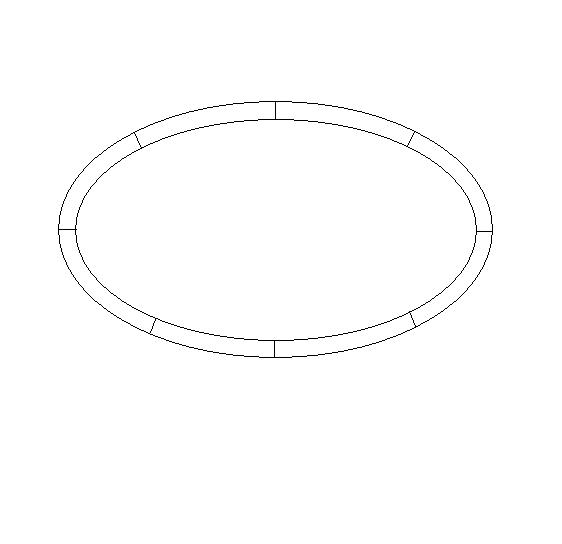

A client of mine wants a table in the shape shown below. The drawing is 42" x 72" with a 2.5" solid band around it. They want it all in solid wood because they want some rough texture on the surface that wouldn't work with standard stock veneer and rough grooves at all the joints. Could this work in all solid wood? I wouldn't glue wide wood 90 degrees, but it would only be 45 in this case. I may lay up the center in 1/16" veneer, but a solid center would be easier. Does anyone have experience with something like this?

Click here for higher quality, full size image

Forum Responses

(Furniture Making Forum)

From contributor D:

I have a client that wants a 24" diameter cherry top with a maple edge around. My first thought was that the only thing that would work would be cherry veneer overlapping the maple edge a bit, but I'm trying to design using a solid or thick self-made veneer.

From contributor J:

I'd expect gaps to open at each end, and the pieces at the ends to loosen after a while. Thick veneer sounds like a much better idea.

From contributor Y:

First, lay out your table on a sheet of plywood. Draw it exactly to size with your border. Then, mark where your joints will lay out most efficiently. Cut your border pieces extra long and join them with an extended lap joint.

Set up an oval guide for your router and rout out your top, the inside and outside of your border, and then you should be good to go. If you are going to be using a plywood or MDF substrate for the field with veneer you should have no/or minimal issues with wood movement. As far as a solid glue up I wouldn’t advise it. If that is not the option make sure you have a 6-7 percent MC and seal it well on all sides.

From contributor K:

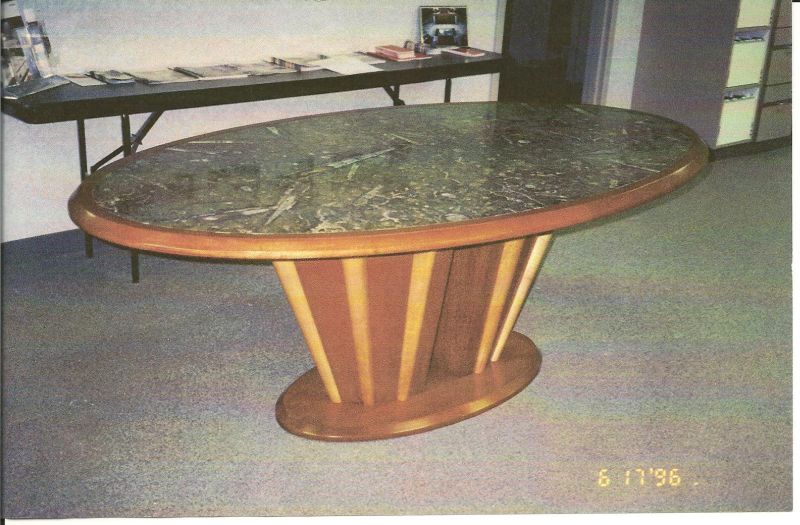

See the table below – it’s 1 1/2" x 2 1/4" solid maple edge and made from four pieces with a joint at each quadrant. The edge is attached to 3/4" particle board substrate and joints are reinforced with dowels.

Click here for higher quality, full size image

From contributor E:

Do not do it with solid wood, it will inevitably fail. You should be able to get any reasonable texture with 1/16" to 3/32" shop made veneer over MDF. Be sure to veneer the underside with the same thickness, cut and species (or a species with similar movement characteristics).

From the original questioner:

I'm doing the center in veneer. I promised the designer that I'd ask others if solid was possible and now I have enough voices to show that it isn't wise. She was basing parts of the design on another very expensive table and asked if they could do this in solid wood, why couldn't I? Of course, when I went to look at it, I pointed out that it was veneer too. I think the showroom had told them it was solid.

From contributor F:

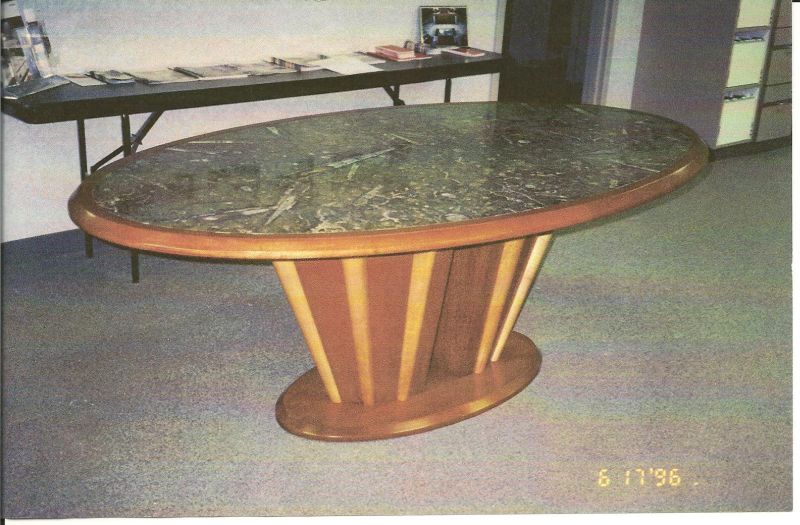

I did this one with floating tenons. It's four years old now and still looks great.

Click here for higher quality, full size image

From contributor C:

Of course the table's field can be made of solid wood. The segmented edge can also be of solid wood, and the whole thing can be designed to allow for seasonal movement. As several others have noted there is no need to. With modern substrates the entire wood movement issue can be minimized and the client will be happier. The use of solid wood would not be a difficult thing to accomplish using joinery and parts designed to allow movement of the field, however, the client probably doesn't understand or want to understand the facts of wood movement so take the position of the expert and explain to the designer and client that the use of solid wood in the table's field would be wasteful, best avoided for the reasons above, and possibly more costly depending on the type of wood specified.

You will be the hero, the designer will have additional respect for your expertise and may just send more work your way. The client will love the new table and will never call you to complain that the joints are cracking, the edges are breaking, or any of the other ways the client might express concern because the table has expanded or contracted. Not to mention they will now have bragging rights to the fact that they chose to use veneer instead of solid wood and are greener for it. Find that eye popping plank for the center field and cut it into amazing veneer and blow their doors off with your skills.

From contributor G:

We make a lot of solid edged tables with glass inserts that leave a bit of room for movement. I would never trap a solid in a solid band. For those that do this, how do you allow for expansion of the center wood? We test solids in the shop and cross grain movement can be a quarter inch on one board depending on the MC of the air in the shop. Our dining tables are either breadboard ends, solid, or a veneer MDF core with a solid band.