Question

I'm at my wits end. I get orange peel with every setting, and every type of finsh applied. I've gone from a 94 air nozzle to a 91, high pressure to low pressure and thinning my lacquer, polyurethane, varnish, to not thinning. Is there anyone who is getting great results using the Binks

Forum Responses

(Finishing Forum)

From contributor R:

I have used Binks Mach 1 for years without trouble. Have you tried a retarder instead of thinning? Orange peel is usually from drying to fast.

Don't count on your Binks distributor to know about this. Mine didn't, so I went to the Binks website and found the parts. When I gave him the part numbers, he ordered the kit and it was easy to install. It makes the gun a little heavier, but not so much as to make you want to remove it.

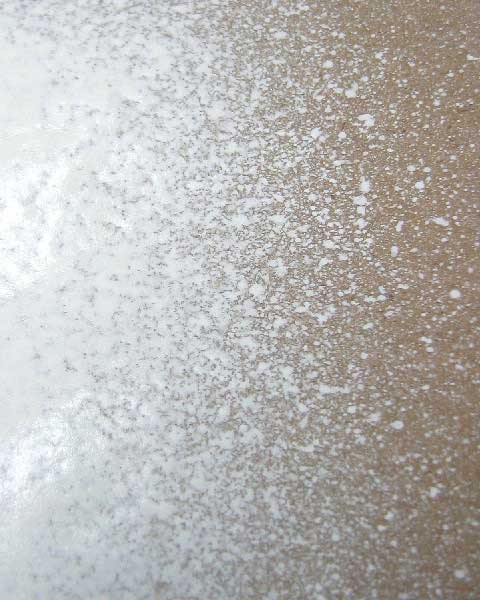

Then make sure the gun is atomizing the finish well. The finish should break up into tiny droplets when you have the settings right. If the finish isn't atomized well, the spray pattern will look more like the picture below on the left. Good atomization looks like the picture on the right.

If you're still getting orange peel once you have the gun atomizing well, make sure you're keeping the spray gun the proper distance from the surface and moving at the right speed to maintain an even wet coat that's not too thin or thick (wet mils). If you're still getting orange peel, then adding retarder should take care of it. There are some tips to eliminate orange peel at this link - Eliminating Orange Peel.

http://www.furniturefinishwizard.com/orangepeel.htm

When everything is working right, the sprayed surface should look almost like glass when it's wet.

* Open the cheater valve at the bottom of the gun handle all the way and leave it there.

* Set the air pressure to the gun at 35-40 PSI.

* Spray a few test shots and adjust the fan width to about 7" wide at 7" - 8" from the nozzle.

* Spray some test spray passes on cardboard, craft paper, or scrap boards and adjust the fluid flow until it atomizes well. If you're getting large droplets, turn the fluid down.

* Now turn the atomization air down to the lowest setting that still gives you good atomization with minimal overspray.

If you use a wider fan pattern, you'll need more fluid and more air pressure.