Supporting a Cantilevered Shelf

but how? Pros share ideas. June 23, 2006

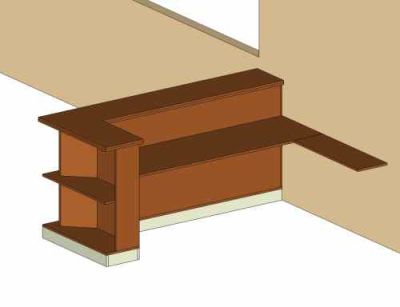

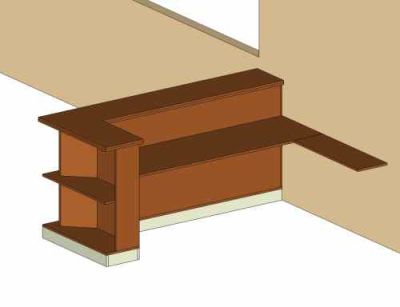

Question

Working with an interior designer who wants a certain look but no support structure to go with it. I need to hang this desk surface off the back of the cabinets, as shown. The desk is 63" long and 24" deep and then there is a 12" x 36" return leg. I can mount ledgers on the cabinets and the wall to support 3 of the 4 edges, but not sure what to do to keep the front edge stiff. Perhaps combo of using two pieces of 3/4" ply with hardwood front edging. Then using 16" or so heavy, right angle shelving brackets like you get at Lowes. Then cover these with trim work. Have no idea as to how much this will stiffen things or the impact of the fact that the shelve brackets are attached to the 3/4" backs of the cabs and whether that will bow the backs when someone leans on the font edge. Love to hear any ideas!

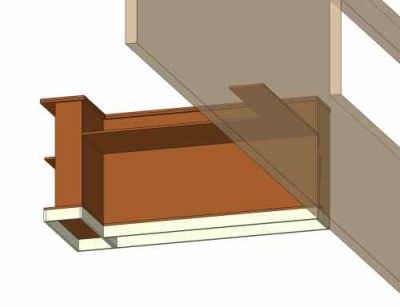

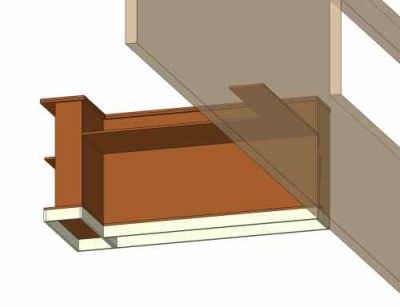

Second view:

Second view:

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor L:

The use of cheap 90º angle brackets would be easy to hide. Have the brackets put into the sheetrock, that is, where the stud is, cut out the sheetrock down to the stud and attach the bracket, then do a patch job on the SR over the bracket. You can even dado the bracket below surface on the underside of the desk and make them the same color so they disappear.

From contributor B:

This could work if the designer would go for it, but would also increase the cost significantly. You could make an "airplane wing" style shelf. It would be approximately 3/4" on the outer exposed edge, but about 3" to 3 1/2" high on the edge attached to the wall. You could make what would in effect be struts and then apply 1/2" ply to the tops and 3/8" bending ply to the curved bottoms. In cross section, it would look like half of an airplane wing... that is, triangular in shape with a concave curve to the bottom as it sweeps down and back towards the wall. With the 3" to 3 1/2" high back, you could easily come up with an attachment method. Maybe crazy, but might satisfy all parties!

From the original questioner:

Yep, planned on the sheetrock trick for the short 12" wide return, but the main 24" section is going against the paneled back of the cabs.

Er... ah... I'd love to propose the airplane to the designer and see what she says... but with my luck she'd spring for it!

From contributor C:

You can plow a dado in the back and sides of a 1 1/2" top and screw corresponding cleats to the cabs and wall. Should be plenty of support for a 63" top.

From the original questioner:

Just signed the commission. We have 6-8 weeks for this and several other built-ins for the client. Yep, I was gonna do cleats around 3 sides, but that leaves the front edge stiffness to deal with.

From contributor D:

Casebuilders need to know how to work with steel. It solves support issues simply, effectively, and inexpensively. We install Corian work surfaces without visible support using welded steel framework. The steel is usually embedded inside the work surface. Talk to a welder. It's cheaper than most people expect, and it's much stronger than any other remedy.

I love designers. They pay all my costs and allow me to do what I love.

From contributor T:

I would stack the upper part of the desk over the shelf, which would extend under the front cabinet (at least halfway). This would allow the shelf to self support. Then stack the lower part of the desk under the shelf. For the return,

Hafele has an adjustable shelf rod for a 3/4" shelf which is mortised into the shelf with a chain mail saw and the supports are anchored into the drywall, giving mortised steel support for the return.

From contributor U:

I'd drop it back into the designer's lap. Provide me with the design and I would be happy to make it. Let her figure it out. It will then really be her design and solution.

From contributor T:

I have yet to meet an interior designer that can tell me how to build a cabinet. (They don't teach any such thing in interior design school.) This is why I meet them in the first place.

We all know that the craftsman has to figure it out.

From contributor A:

I just supported 51" of a granite countertop with a similar configuration. I used a ledger along the sides and back, and supported the front with a steel bar. I went to a local welding shop and they cut me a 1" square bar to the desired length and it cost me $15. Then I simply notched the ledger so that the top of the bar was flush with the top of the ledger. The bar was set 3" from the front edge and with the bullnose, it is completely hidden unless you're on your hands and knees. With 200 lbs on it, it barely deflected 1/8".

From contributor K:

Here's a picture of some free-standing shelves. Thicker than what you might be looking for, perhaps. Torsion box, in the direction of contributor B's suggestion, is 3 inch grids of 1 3/4 maple skinned with 1/2 birch ply, and fastened to the wall with a steel bracket (3/4 round tines welded 12” OC to flat steel, lagged directly to studs - the shelves simply slide over them) as contributor D suggests. The brackets might be overkill, but it never hurts to be safe, and I got a steal on them.