Message Thread:

spoil board

7/27/18

I have a 5 x10 router and at times when cutting parts such as small stretchers they have a tendency to move a little when they are on the edges of the board (even when I tab them) This is mostly when I use prefinished 3/4 plywood. My software seems to always put the stretchers on the outside edge of the sheet to compound the problem. Also when using onesided prefinsihed some times it is hard to keep one corner down. My question to you has anybody tried shifting the orgin to say 6,6 and get the edge of my material away from the edge of the spoil board? I mean we have a 5 x 10 table and basically only cut on the first 4x8 when cutting plywood. Just thought of it today when I was trying to hold down that pesky corner at the origin.

7/27/18 #2: spoil board ...

That may work, you could certainly try it. Are you blocking off the unused portion of the table also? What pump(s) are you using? What level of vacuum do you develop at the beginning of the sheet and what does it get to by the end?

7/28/18 #3: spoil board ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

What software are You using ? many will allow for cut pattern to cut smallest parts first (Max Vac) or move them more centered to the nest. We are cutting 6 x 9 or 12 drawer fronts and stretchers (probably smallest parts we cut) what size and type of vac and is plenum divided into segments. Like bill said covering unused area to stop vac loss, basically it is just another strategy wanting a sweet spot.

7/29/18 #4: spoil board ...

What is needed, like Yakov (sorry If I murdered the spelling of your name) said a few months ago is an algorithm. You need to, like I have been doing for many years, and this is the most tedious thing that I do in my life, is to order the start and stop points as elegantly as possible to begin and end at a point already connected to the remaining nest. To state simply, if you have 10 small stretchers surrounding a large base cabinet side, first set the start and stop points of the small parts to tend to the center then set the cut order to first cut the outer (or smaller) parts then the inner (or larger) parts so that the last part cut is one that will not move.

It is not so difficult really, a minute or so for a sheet of typical cabinet parts with a little practice, but you will loose very few parts, even with poor vacuum.

Prefinished ply is the most difficult to cut. Some brands, I happen to like Garnica, it seems to remain relatively flat, the corners suck down well mostly no matter what face is up. The 7 ply Columbia works well too. If you can orient the outer edges concave down it helps a lot.

7/30/18 #5: spoil board ...

thanks Mark ,no you not "murdered" my name

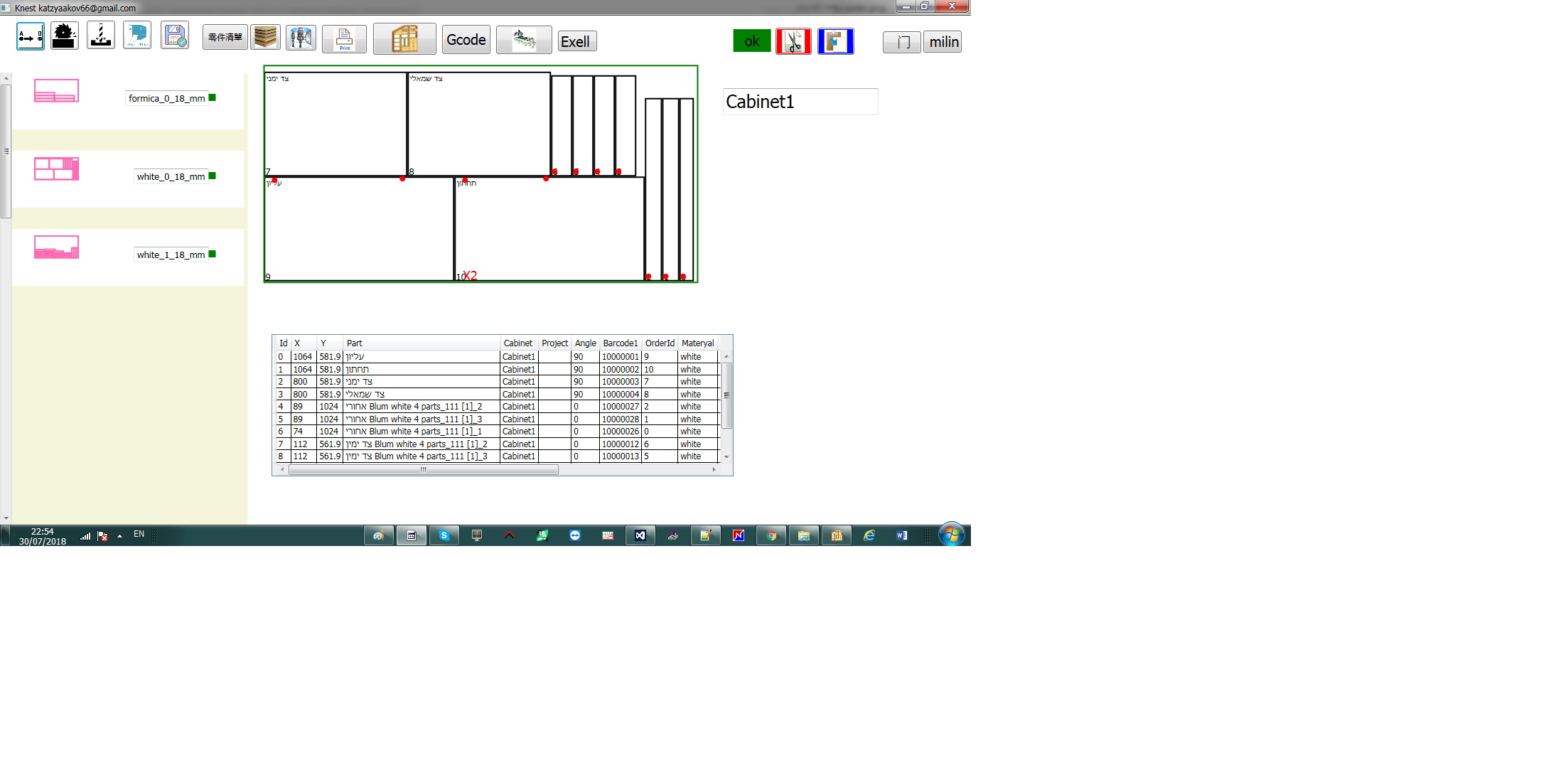

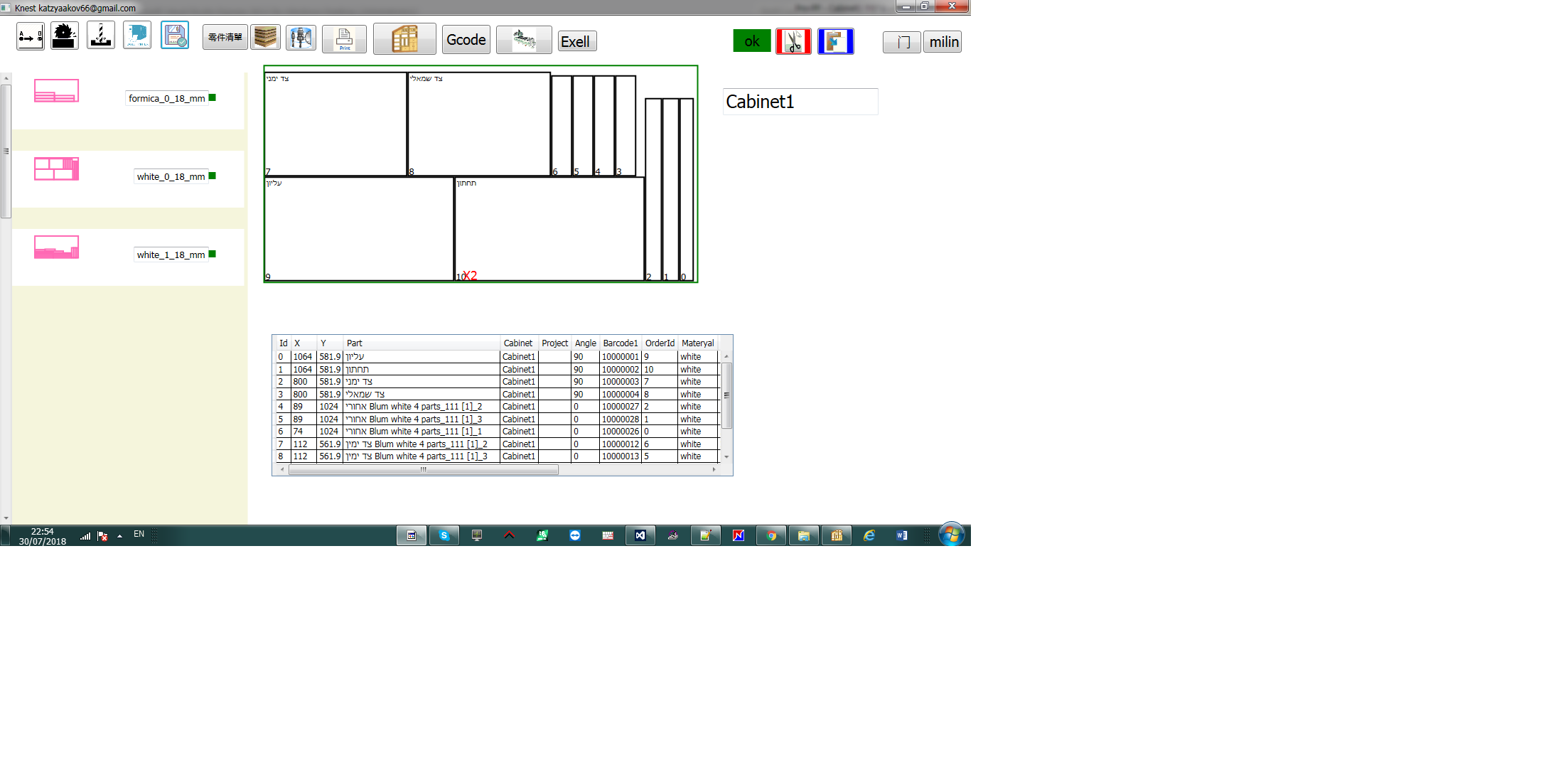

i attach one sample ,you can see the order of cutting parts and the lead in point

this sample cut in one time (no onion skin neded) with 6mm diameter tool

about 15 m/min

with only one vacuum pump 250 m3/h

nothing moove

you can see that only last part we use onion skin (its according remind mm3 ,part of the algorithm)

View higher quality, full size image (2206 X 1076)

View higher quality, full size image (2206 X 1076)

7/30/18 #6: spoil board ...

Yes that is very simple, very simple indeed. Why I did not see that I can not explain. I guess I could not see the algorithm for the trees. I do not know how the software I use places pieces on the sheet, or how it places start and stop points. It does do onion skin and tabs but how it determines where they are is also way above my pay level. I know that it will cut plywood stretchers with the grain since plywood does have a grain, and I can switch off the grain for solid color melamine, where it will optimize all parts for optimum yield, however since my 5 mm drills are set up in the x axis and my different size drills are in the y axis I have to leave the grain on so it won't chicken peck my adjustable shelf holes. I can guess that what you are saying will be in the g-code which I know a little bit about but I can not read it like a second language. I do appreciate your time and effort in trying to help me, maybe you could explain it in a way that I could understand, your maybe there is just no help for me, its that thing about old dogs and tricks

7/30/18 #7: spoil board ...

You are using a very small bit and going really slow so the forces can't be very high. That leaves the material which is slick, &/or warped and the vacuum level at the part. if you haven't paint or band the edge of the spoil board to reduce leakage. Cover any unused areas with laminate or something that will suck down flat. Resurface the spoil board often. Check/clean the filter on your vacuum system. What does the vacuum gage read while cutting?

7/30/18 #8: spoil board ...

15 meter / min its not slow

the vacuum can show from 0.5- 0.75

7/31/18 #9: spoil board ...

Larry is correct. Sealed edges are needed.

Your edge banding will flake off though, when fly cutting. The easy solution is to run it through the edge bander with no tape. Remember to back off the pressure wheels so you don't make a mess.

I wrote this a few years back.

https://www.woodworkingnetwork.com/custom-woodworking/cabinet-making-case-studies/

4-Steps-to-Surfacing-MDF-Spoilboards-195405851.html

8/23/18 #10: spoil board ...

To Katz. I saw the picture of the nested parts. I have used many programs to nest, my fav being Alphacam. None are perfect. As in the picture you have the parts you want to cut first all the way at the end. I am guessing your X0Y0 is lower left.. I would have modded that layout by basically rotating it 180 Deg, doing the thin parts first, then moving into the large parts that do not succumb to vacuum losing strength as pieces are separated from the panel. You can order toolpaths, right? That's key to working around less than ideal vacuum. Strategize. Choose start points correctly. Maybe do the narrow boards in 2 passes and the large panels you can blow through with a 3/8 comp @ 850" a min. Less waste.

8/24/18 #11: spoil board ...

@Rich about axis yes you corect we usualy use the europain style ,that mean long axis is X

about parts order you can see the number ,one thing very important its the lead in point ,always in the side close to center ,and near corner ,so most cuting ,part stick well to main board

in mine nesting all that calculate by software ,you dont need change by manual

can cut one time ,with 6 mm diameter tool speed about 15 m/min

|